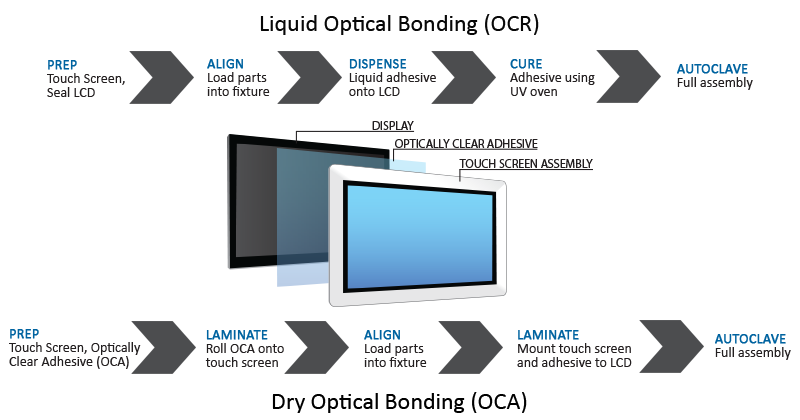

Touch international is an expert in all of the ways to assemble and laminate p cap touch sensors including oca or optically clear adhesive using pressure and heat dfa or dry film adhesive using vacuum and heat ocr or optically clear resin using heat and uv radiation and two part epoxy using chemical cross linking.

Touch panel lamination process.

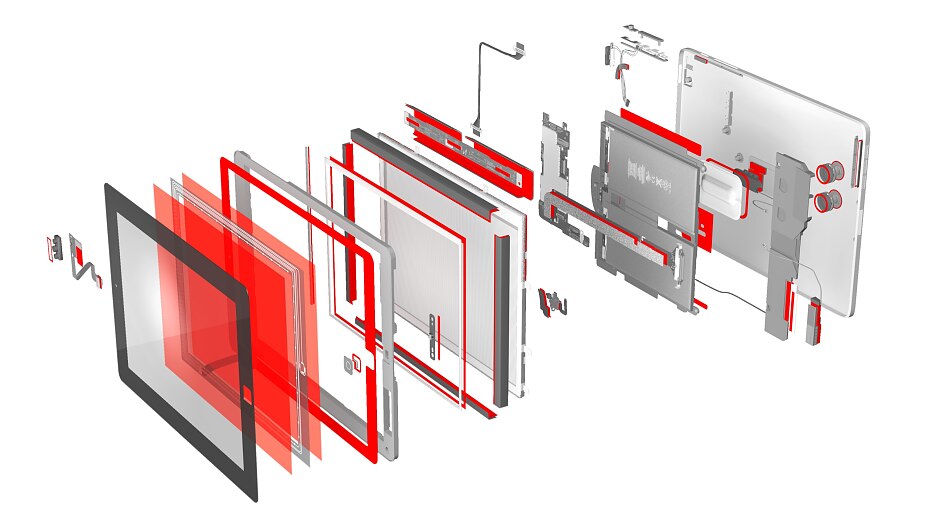

A touch panel system may include.

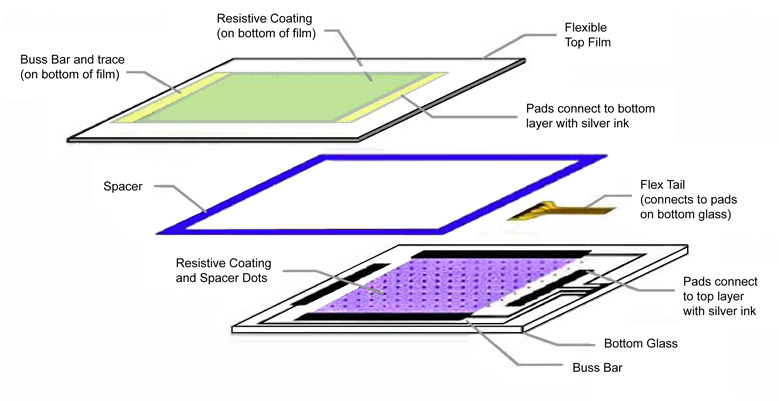

The capacitive touch panel contains three layers.

Inconsistent process stability and lamination results air entrapment in the lamination layer poor lamination allowing delaminating to occur inconsistent pressure on the panel causing cracking or damage wrinkling or deformation of the lamination layers creating irregular appearance and performance wrinkling.

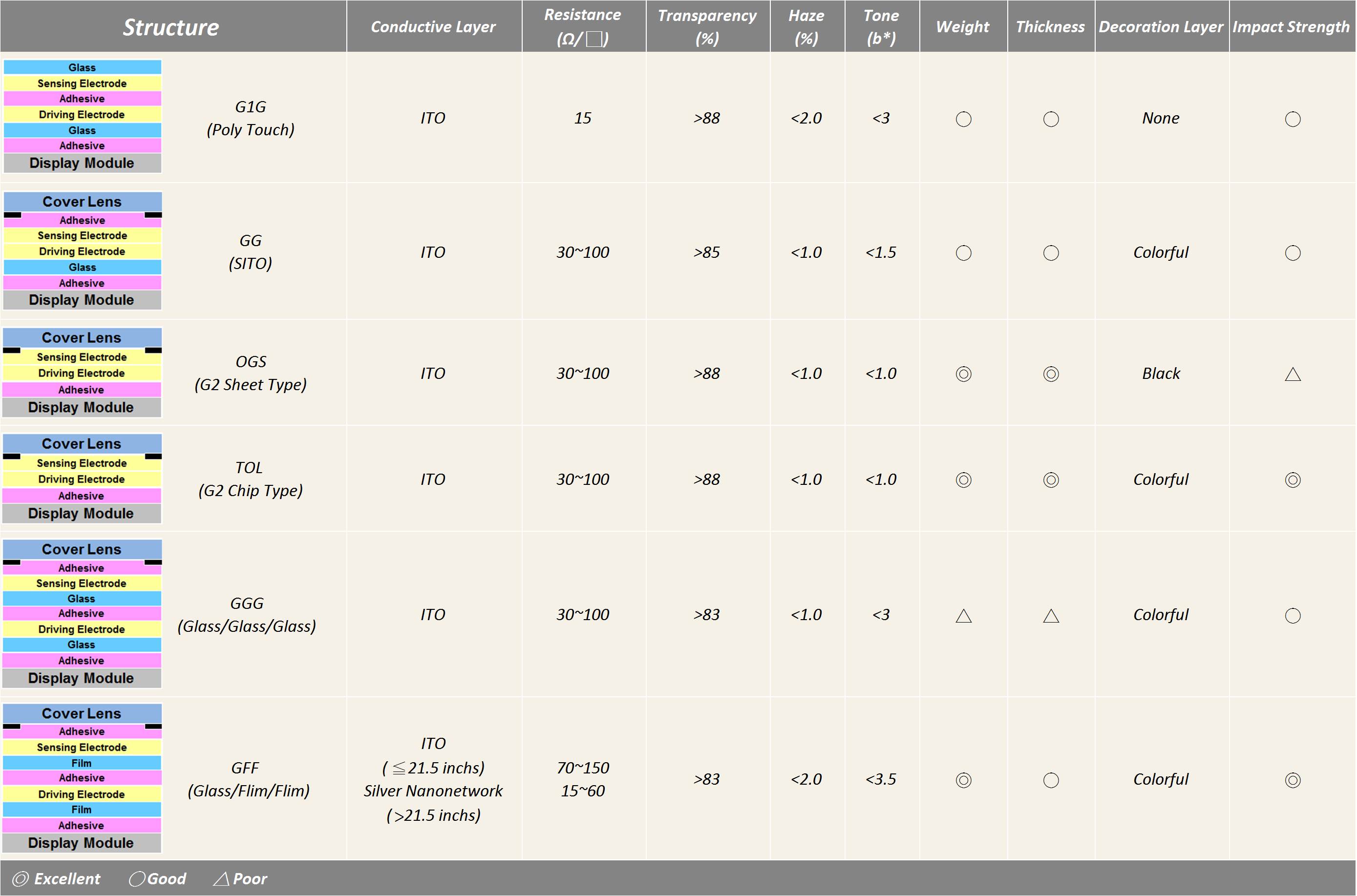

The process and components of the touch panel seem to be simple but in fact the touch panel process is very varied.

Touch panel completion lamination coating uv curing oca lamination ocr coating lamination coating uv curing screen printing coating glass uv hardening fluoro coating acf tape joining polarizing plate joining cog joining touch sensor production process setup stage lcd panel completion 2 2 tft array stage color filter stage.

In order to function as intended display and touch panel modules require better than 5 micron alignment of the many film layers.

For your specific requirements we offer various tried and true lamination techniques cleanroom conditions and a 100 performance test.

A touch panel system and process are disclosed.

In addition to precision and speed the solution needs to be flexible enough to handle different camera and motion configurations and scale rapidly for high volume manufacturing and rapid product change over.

Inquisitive at last a question testing touch guy s expertise.

When used in conjunction with fast tack pva adhesives the panel express laminating system allows you to move from.

A process for manufacturing a touch panel system may include one or more of the following.

We combine projective capacitive touch sensors pcap with your panel through lamination.

Panel process machinery panel laminator presses one piece flow.

Gyti a high performance industrial process technology company announced that it filed a provisional patent application earlier this month for its equipment and technology for laminating cover glass to displays such as touch panels and lcd s using adhesive film.

The all round bonding technology is to glue the panel directly to the outer glass or touch panel with glue.

And a deformable glass substrate.

Each layer is basic on substrate glass.

In terms of technology the front end process and the back end process are highly variable and growing.

Berliner glas is there to help you find the right solution.

Panel express heat assisted rotary laminator is designed to laminate all types of hpl and most veneers to particleboard or mdf down to individual parts 44 long.

Then put the cover glass onto the top.

Before and during each process cleaning is very important.